The Pallet Mole®

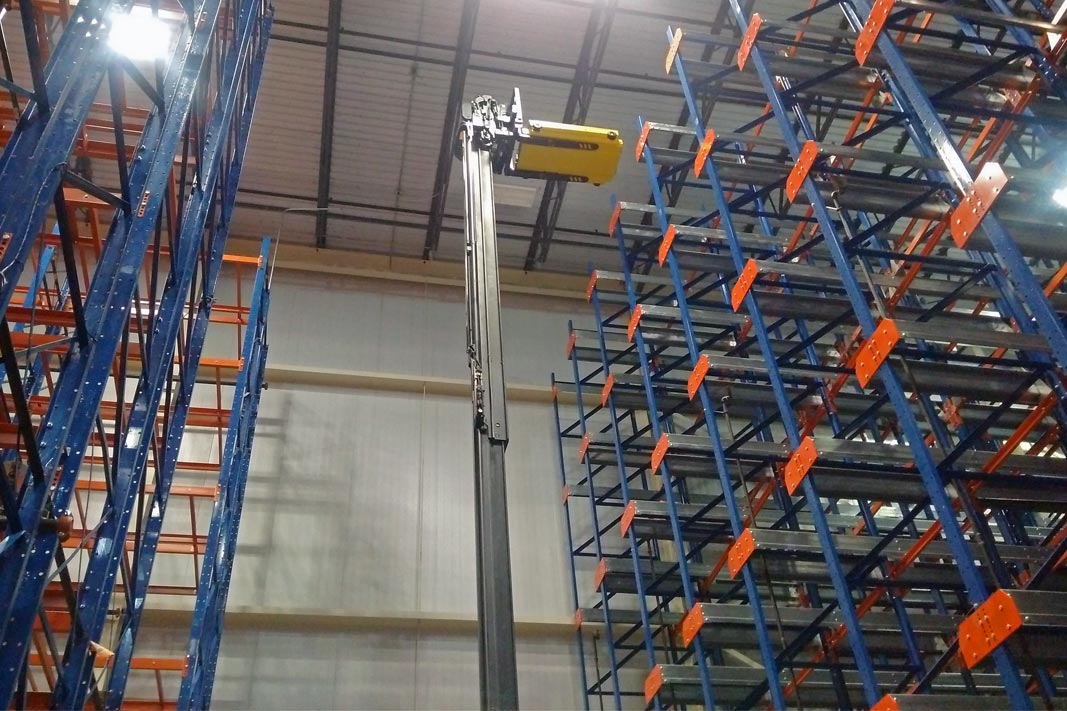

Utilizing the latest technology in compact, high density storage, FRAZIER’s semi-automated Pallet Mole® systems optimize floor space while measurably increasing productivity.

High Density Pallet Rack Storage

When it comes to choosing the best high density Storage Solution for your business, there are a number of critical factors to consider – cost, space availability, throughput and SKU (Stock Keeping Units) counts all play an important role in selecting the proper storage solution for your operation. The Pallet Mole® offers the following advantages over traditional storage solutions:

- Maximizes density over 6-high and 50 pallet positions deep

- Increased pallet positions and through put by up to 30%

- Allows for a truck to be loaded/unloaded in less than 30 minutes

- Ideal for both FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) applications

- Optimizes labor efficiency

- Enhances accuracy of inventory control

Semi-Automated Shuttle

The Pallet Mole® runs underneath the pallet loads on rails, delivering and extracting pallets within a deep lane rack system. Working in either FIFO or LIFO applications, the Pallet Mole® significantly improves throughput by indexing loads directly to the first pallet position at the aisle face. Using a RF controller or Wi-Fi compatible device, the operator can instruct the electro-mechanical platform to lift, lower, or shuttle pallets to the desired position; or program the system to run various predetermined functions. 4 wheel drive and an optimal battery life for cold storage make the Pallet Mole® adaptable to a variety of applications.

- Single and double wide options available

- High performance travel speed

- AC driven technology

- Patented pallet count system

- Pallet shuffle function

- Full two-way communication between Pallet Mole® and controller device

- 4 wheel drive options

- U.L. Certified

- Built-In positioning control

- Electro mechanical, flat deck lifting system

- Magnetic Latching

- Dual spacing system

- Battery low function

- Optional No Bottom Beam design for increased sanitation

Developed as Frazier’s response to strict updated fire code requirements, the Pallet Spacing System & Method Patent allows is a key value add across the Pallet Mole rack solution.

It allows users to be code compliant by managing a 6″ spacing between pallets sorted in the rack system. The 6″ spacing is maintained in both the front-to-back direction as well as in vertical alignment. Watch to learn more:

- “What really drove the decision was how fast we could effectively load the system and offload to the truck with a limited number of operators. With a 25-deep, 40-wide Pallet Mole® system only feet from the bottling line and the loading dock, we are extremely confident that we’ll reach our goal of twenty minutes per truck load in Kansas City.” – Bernie Zarda, Vice President, Premium Waters

- “Frazier is a Five Star company and I give my full recommendation of them across the board. We have most recently installed the Pallet Mole® solution which has been a major success in our warehouse. We look forward to working on future projects with Frazier’s skilled Account Management and Project Management Teams.” – Michael Becht, General Manager, Bartlett Dairy & Food Service